TIGER 6

The ROPA Tiger 6, the most powerful sugar-beet lifter in the world, will be introduced to the world at the Agrosalon trade fair and it will be awarded a gold medal for innovation for its overall design. The heart of the machine is the new 700 hp or 768 hp engine with pump-nozzle injection and 16.12 litre capacity. Compared to the Tiger 5, power has been increased to 105 kW (142 hp). The new machine design has a perfectly integrated drive system with automatic slope compensation and is extremely gentle on the soil. The more powerful bunker-emptying mechanism provides faster truck loading on the move. The comfort cabin with glass touch terminal, WLAN interface and numerous automatic programmes offers top driving comfort for the best lifting results.

VOLVO ENGINE 16.2 LITRE DISPLACEMENT – 2 OPTIONS

The power transmission in the 515 kW (700 hp) ROPA Tiger 6 with its Volvo inline 6-cylinder engine (emission level EPA 4 final), 16.12 litre displacement, pump nozzle injection (PNI), SCR catalytic converter and AdBlue is now even more efficient.

For even more power in the Tiger 6 ROPA offers the 565 kW (768 hp) Volvo inline 6-cylinder engine with 16.12 litre displacement and pump nozzle injection (PNI). The robust power pack does not require AdBlue, SCR catalytic converter and exhaust gas recirculation.

LIFTER ATTACHMENT – 2 OPTIONS

All ROPA lifting units have a fully hydraulic drive for the complete lifting unit. Lifting units in 6, 8 and 9 rows are available with different row widths. The row width of 6-row variable lifting units can be optionally adjusted from the cabin.

All lifting units offers an excellent view across the lifting unit; the operator watches the beet row and the operation of the Micro-Topper Every share body with its maintenance-free linear guide fits up to 70 mm to the side of the beet row. Long tension rods minimise transverse forces and also simplify row adjustment.

Non-jamming PR lifting unit with hydraulic stone protection

The PR2h lifting unit is equipped with counter-rotating oscillating shares and completely maintenance-free hydraulic stone protection. The 900 mm large depth-control wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Maintenance costs are minimised with adjustable taper roller bearing in drives and shaking share drive.

Weight-optimised RR lifter with single-row adjustment

The RR lifting unit is equipped with counter-rotating shaking shares, seven lifting rollers, completely maintenance-free hydraulic stone protection and single-row adjustment of the lifting depth. The 850 mm large depth-control wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Maintenance costs are minimised with adjustable taper roller bearings in transmissions and the oscillating share drive. The convenient maintenance position lifts the defoliator and the lifting group 90 degrees for simple inspection and service of defoliator knives, scalper knife and lifting shares

R-SOIL PROTECT

For even higher soil protection

ROPA R-Soil Protect is combination of a soil-protective, hydraulic chassis system with new MICHELIN CerexBib tyre technology. This soil protection concept was awarded a silver medal at Agritechnica in Hanover. It only requires 1.4 bar tyre pressure and it is available as an option in the Tiger 6. The synergy of the load-balancing hydraulic chassis with the new generation of MICHELIN IF1000/55 R32 CerexBib tyres offers even more contact surface with sustained soil protection and significantly reduced contact pressure.

ROPA has developed an innovative chassis concept with an oscillating front axle in conjunction with two hydraulically supported rear axles specially for the flagship Tiger. Compared to the chassis on previous 3-axle beet harvesters (with the central axle fixed to the frame), this reduces the sway of machine by one third! The reason for the improvement is the hydraulic connection of the cylinders at the front and rear axles on one side, so unevenness at one wheel at a different level only affects the frame by 33 per cent compared to the previous system. Thanks to the reduction of the chassis swing, the row and depth control are improved simultaneously, as the frame is averaged to the position of three axles. The hydraulic connection of the axles always distributes the load equally over all 6 wheels.

HYDRAULIC CHASSIS SYSTEM

Slope compensation up to 10%The automatic levelling system using six hydraulic cylinders and sensors is unique among 3-axle beet harvesters. The chassis is kept completely horizontal for up to 10 percent side slope. The gravity centre and, thus, the load of the wheels on the slope bottom side are shifted to the slope top side.

Schwerpunkt Bodendruck wird ausgeglichenThe track depth of the wheels on the slope bottom side is substantially reduced, the infiltration capacity is retained, thus significantly reducing erosion risk during heavy rains. The slope stability and traction increase greatly, the risk of tipping over is considerably reduced alongside with increased driving comfort.

AUTOMATIC SLOPE COMPENSATION

STEPLESS CVR GEARBOX FOR EFFICIENT POWER TRANSFER

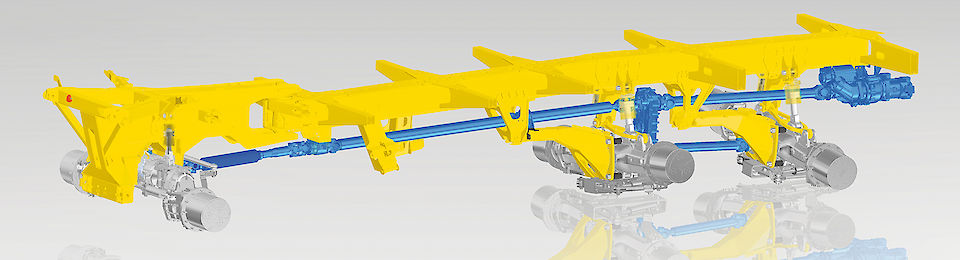

Direct power transmission with cardan shafts ensures even traction at all wheels with very high torque

As a unique selling proposition on the market of 3-axle sugar beet harvesters, the Tiger has a direct power transmission via directly linear situated cardan shafts from traction drive to both rear axles and front axle, which is a great advantage for better traction in changing or difficult soil and harvesting conditions.

Thanks to hydraulic chassis the load is always distributed evenly. Thus, lead or lag between the axles are consistently excluded.

Stepless CVR gearbox for efficient power transfer

The new stepless traction drive was specifically developed by ROPA, Omsi and Bosch Rexroth for the ROPA Tiger with its high drive power. The ROPA constant variable transmission (CVR) consists of three hydraulic motors on a compound gearbox and is located between the engine compartment and the third axle.

NEW CABIN AND OPERATING CONCEPT

The easy-care, pleasant and attractive interior of the new cabin guarantees the most comfortable operation. There are generously dimensioned shelves, storage compartments and plenty of space around the driver. A cooler and the integrated seat ventilation for hot days and seat heater for colder weather are standard equipment. Extremely powerful fully LED working lights turn night into day.

Intuitive dual operating concept – ROPA combines under the name R-Concept its new intuitive operating philosophy. A large 12.1 inch touch screen is the information and command centre of the machine. From here the operator monitors the entire machine, receives information about operating conditions and performance data, adjusts functions and the working results of the machine.

IMPRESSIONS

In summary, new developments of the Tiger 6 increase the daily output at reduced operating costs, simplifying maintenance and repair. The operator experiences improved driving comfort with more economical, efficient and soil-protective harvesting of sugar beet.