TIGER 6

ROPA is pushing forward to a new performance dimension with the Panther 2. Sporty modern design with manoeuvrability and agility combines with a “workhorse” in the new Panther 2 for pure pleasure when lifting beets. There are sufficient power reserves for the most extreme lifting conditions, and using XL lifting attachment demonstrates the centrepiece of it all: the new 700 hp or 768 hp Volvo inline engine with pump-nozzle injection and 16.12 litre capacity. The award winning and soil-protecting chassis system with roll stabilisation and automatic slope compensation have been flawlessly integrated into the new machine design. The unloading conveyor derived from the Tiger 6 with a more powerful hopper emptying facilitates quicker loading during the drive. The new comfort cabin with glass touch terminal and numerous automatic programmes is the basis for outstanding driving comfort and the best lifting results.

VOLVO ENGINE 16.2 LITRE DISPLACEMENT – 2 OPTIONS

The power transmission in the 515 kW (700 hp) Panther 2 with its Volvo inline 6-cylinder engine (emission level EPA 4 final), 16.12 litre displacement, pump nozzle injection (PNI), SCR catalytic converter and AdBlue is now even more efficient.

For even more performance in the Panther 2, ROPA offers the 565 kW (768 hp) Volvo inline 6-cylinder engine with 16.12 litre displacement and pump nozzle injection (PNI). The robust power pack does not require AdBlue, SCR catalytic converter and exhaust gas recirculation.

LIFTER ATTACHMENT

All ROPA lifting units have a fully hydraulic drive for the complete lifting unit. Lifting units in 5, 8 and 9 rows are available with different row widths. The row width of 6-row variable lifting units can be optionally adjusted from the cabin.

All lifting units offers an excellent view across the lifting unit; the operator watches the beet row and the operation of the Micro-Topper Every share body with its maintenance-free linear guide fits up to 70 mm to the side of the beet row. Long tension rods minimise transverse forces and also simplify row adjustment.

Weight-optimised RR lifter with single-row adjustment

The RR lifting unit is equipped with counter-rotating oscillating shares, seven lifting rollers, completely maintenance-free hydraulic stone protection and single-row adjustment of the lifting depth. The 850 mm large depth-control wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Maintenance costs are minimised with adjustable taper roller bearings in transmissions and the oscillating share drive.

ANTI-SHAKE AND BALANCE SYSTEM

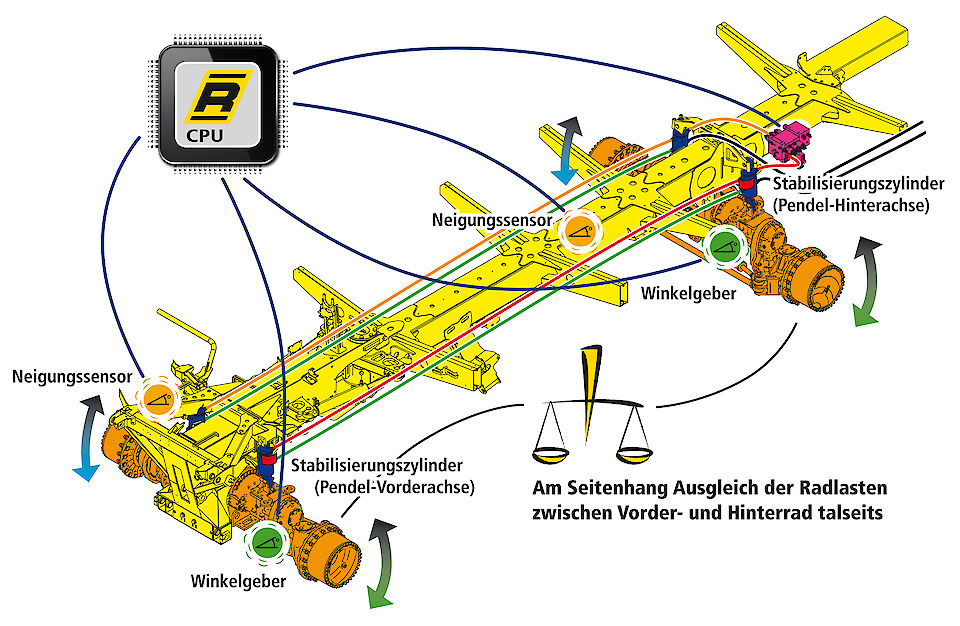

Chassis concept with wheel load compensation system and computer-controlled slope level adaptation

The ROPA Panther 2 has an innovative chassis concept with 2 floating axles in conjunction with 4 stabilising cylinders. Compared to conventional chassis of 2-axle beet harvesters this reduces the sway of machine by 50 per cent. The reason for the improvement is the hydraulic connection of the stabilising cylinders at the front and rear axles on one side, so unevenness at one wheel at a different level only affects the frame by 50 per cent compared to the previous system. Thanks to the reduction of the chassis swing, the row and depth control is improved simultaneously, as the frame is averaged to the position of both axles.

FULLY AUTOMATIC SLOPE COMPENSATION

ON A SIDE SLOPE THE CHASSIS IS INCLINED TO THE SLOPE

MANOEUVRABILITY

The sporty and agile Panther

- TOP manoeuvrability with 60° articulation angle

- Optimal articulation position – 1650 mm behind the front axle

- The chassis tilts to the centre of the circle during fast travel around curves

- Easy harvesting, even on small fields

- Small turning circle

- 40 km/h road travel at only 1265 rpm.

NEW CABIN AND OPERATING CONCEPT

The easy-care, pleasant and attractive interior of the new cabin guarantees the most comfortable operation. There are generously dimensioned shelves, storage compartments and plenty of space around the driver. A cooler and the integrated seat ventilation for hot days and seat heater for colder weather are standard equipment. Extremely powerful fully LED working lights turn night into day.

Intuitive dual operating concept – ROPA combines under the name R-Concept its new intuitive operating philosophy. A large 12.1 inch touch screen is the information and command centre of the machine. From here the operator monitors the entire machine, receives information about operating conditions and performance data, adjusts functions and the working results of the machine.

IMPRESSIONS

In summary, new developments in the Panther 2 increase the daily output at reduced operating costs, simplifying maintenance and repair. The operator experiences improved driving comfort with more economical, efficient and soil-protective harvesting of sugar beet.